Office Carousel

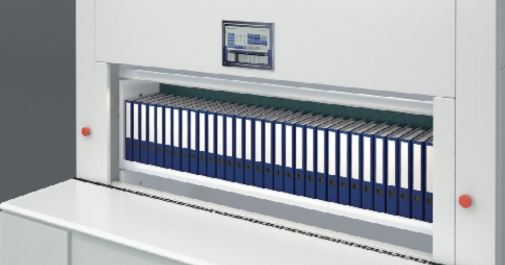

Introduction to CD Series Automatic Layer Selection File Cabinet.

Structure Description

- Closed enclosure

- Drive system

- Power unit

- Load Shelf

- Workbench

- Power and function selection board

- Computer automatic control board

Main Functions

- Automatic layer selection and leveling

- Automatic proximity selection

- Emergency manual electric

- Temporary hand crank for power failure

- Photoelectric safety protection control

- Error alarm

- Computer network control

- Computer- controlled automatic doors.

- Touch screen control

Guarantee service quality to meet customer needs - A professional file automation management solution

Product Feature Options

- RFID real-time monitoring and positioning.

- PLC RF barcode management

- PLC touch screen management control

Maximize Your Office Space with the Office Carousel!

- Smart Storage. Easy Access. Total Efficiency.

- Automated Vertical Storage – Save space & stay organized

- Touchscreen & Computer Control – Quick & effortless retrieval

- Secure & Reliable – Advanced safety & error protection

Upgrade your office today!

File cabinet control management

Archive information management

Real-time monitoring of file entry and exit

Archive Statistics

RFID radio frequency real–time inventory is located to this automatic layer selection file cabinet

Main Overview:

To enhance security and encryption, RFID radio frequency identification technology has been added to the original PLC automatic layer selection cabinet. With the network’s control the location of the target file can be precisely located, and the record management of the file can be efficientlv handled.

To enhance security and encryption, RFID radio frequency identification technology has been added to the original PLC automatic layer selection cabinet. With the network’s control the location of the target file can be precisely located, and the record management of the file can be efficientlv handled.

Inventory positioning accuracy of 100%, a single inventory time is less than 3S to achieve “disorderly storage and orderly management“

Functional modules

- Host computer remote automatic inventory system

- RFID radio frequency management file.

- Emeraency hand crank to open and close the door.

- Network control manage

- The system has a slow start and slow stop fur

- A real-time automatic inventory of the lower

- Running Status Display

- Automatic door opening and closing

- Report export printing

- Touch screen screen control cont

- Multi-host multi-user control

- Photoelectric safety protection

- RFID Radio frequency real-time monitoring

- Run Log

- ED digital display is located.

Software Module

- System login

- File Login/Registration

- Manage file records

- Initial setup

- User management

- File Receipt/Query

- File return/registration

- Borrowing record management

- Extended field settings

- File sending/system

- Archive information Maintenance

- Database management

- Field Content management

| Model | CD-9R | CD-10R | CD-11R | CD-12R | CD-13R | CD-14R | CD-15R | |

|---|---|---|---|---|---|---|---|---|

| Overall dimensions (mm) Length × width × height | Motor external | 1860 × 1200 × 2310 | 1860 × 1200 × 2500 | 1860 × 1200 × 2690 | 1860 × 1200 × 2880 | 1860 × 1200 × 3070 | 1860 × 1200 × 3260 | 1860 × 1200 × 3450 |

| Motor built-in | 1860 × 800 × 2660 | 1860 × 800 × 2850 | 1860 × 800 × 3040 | 1860 × 800 × 3230 | 1860 × 800 × 3420 | 1860 × 800 × 3610 | 1860 × 800 × 3800 | |

| Layer | 9 | 10 | 11 | 12 | 13 | 14 | 15 | |

| Storage baffle specification (mm) Length × width × height | 1490 × 250 × 340 | 1490 × 250 × 340 | 1490 × 250 × 340 | 1490 × 250 × 340 | 1490 × 250 × 340 | 1490 × 250 × 340 | 1490 × 250 × 340 | |

| Weight (kg) | 370 | 400 | 430 | 460 | 490 | 520 | 550 | |

| Maximum allowable load per layer | 70 | 70 | 70 | 70 | 70 | 70 | 70 | |

| Stable file | File box thickness 35mm | 333 | 370 | 407 | 444 | 481 | 518 | 555 |

| File box thickness 50mm | 243 | 270 | 297 | 324 | 351 | 378 | 405 | |

| Motor power | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | |

| Maximum pickup time | 15.5 | 17 | 18.5 | 20 | 22 | 23 | 25 | |

| Minimum pickup time | 3.4 | 3.4 | 3.4 | 3.4 | 3.4 | 3.4 | 3.4 | |

Why Choose a Smart File Cabinet?

Compared to traditional file cabinets, the storage capacity is greatly increased and the dedicated management

Compared to traditional file cabinets, the storage capacity is greatly increased and the dedicated management

platform automatically selects automatic shortcut layers and real-time inventory positioning to the original.

According to the actual use of the warehouse, different types of automatic layer selection filing cabinets can be

selected at different heights, making full use of the warehouse space, saving a lot of warehouse floor space (saving

40% -60% of warehouse area), reducing infrastructure investment and scale. Adopting a high-quality steel plate

with a fully enclosed shell design, the stored items meet the requirements of anti-theft, dust-proof. fireproof, and

anti-glare. At the same time, a photoelectric protection device has been installed to ensure the safe operation of the

staff.

A lightweight rotary storage system that provides a single-layer load-bearing up to 100kg, with simple operation

control based on a touch screen, can be connected to multiple machines, docking scanning gun, docking LED cargo

position indication, and rich and diverse function expansion.

Revolutionize Your Document Management with the RFID Smart Office Carousel

- Office Carousel – Smart RFID File System

- Fast & Automated File Retrieval

- Secure & Authorized Access

- Real-Time Tracking & Monitoring

- Boost Efficiency & Save Time

- Seamless System Integration

Product Description

Product materials and technical indicators

- The main materials used for the fully enclosed shell and internal structure are high-quality carbon structure cold-rolled steel wrenches, which meet the national standard GB912. Through the process of shearing, bending molding, and stamping, the structural rigidity and strength of the cabinet are increased, resulting in the machine having the benefits of light weight and firm structure.

- The powe pwer transmission system is powered by a well-known domestic brand of geared motors. The product is a beautiful and sturdy ribbed high-steel cast iron box. The surface of the gear is carburized and hardened, making it durable. It has low vibration, noise, compact internal structure, small size fine transmission ratio, high transmission power, and excellent performance and quality. It forms the perfect combination of gears that rotate.

- The surface process of the filing cabinet is electrostatic sprayed. This product is processed through a plastic spraying line, and the color can be selected according to user requirements. The impact resistance of the paint film of the product meets the GB/T1732-1993 standard and the chemical resistance of the paint film meets the GB/1763-1979 (89) standard. The adhesion of the paint film meets the GB/1720-1979 (89) standard. It has the benefits of a bright surface shine and uniform color thickness.

- To ensure safety, the control console is made of non-metallic wrenches (fireproof veneer high-density medium fiber wrenches), which play a role in fireproof insulation without deformation. Electrical appliances, parts, and computer boardsIs are installed in pplastic isolationoverhead.

- All electrical components are strictly selected and are domestic high quality and are insured by the People’s Insurance Company of China. All electrical components are marked by the People’s Insurance of China, the company’s product quality insurance logo. quany suraice lgo. 6. The mechanical transmission, chain, and sprocket selection of 10A and 16A single-row chain; technical indicators are in line with the national standard IS 060 standard, 16A type of ultimate tensile load is a minimum of 3200kg. according to our factory design of automatic laver file cabinet actual load is less than 1000kg. so it will not cause mechanical fatique or extension. There is a large strength redundancy.

Power and safety protection

This product uses a three-phase four-wire 380V power supply and a 220V single-phase power supply. It can be purchased to meet the needs of the user. user Each cabinet is equipped with an automatic air switch and the door is equipped with infrared light control protection. There is a limit switch for incoming calls when the power is off. If there is a leakage, the air switch will automatically trip.

This product uses a three-phase four-wire 380V power supply and a 220V single-phase power supply. It can be purchased to meet the needs of the user. user Each cabinet is equipped with an automatic air switch and the door is equipped with infrared light control protection. There is a limit switch for incoming calls when the power is off. If there is a leakage, the air switch will automatically trip.- Over-current protection: To prevent the drive motor of the selected layer filing cabinet from overloading (mechanical, partial failure or electrical failure), a three-phase circuit breaker (5-8A) is installed at the front end of the electrical control board, usually set to 5A.

- Overheating protection: To prevent motor or appliance from overheating and burning out, a thermal relay is installed at the front end of the motor.

- Safe isolation; in order to ensure the safety of storage, it is required to use a rubber flexible cable larger than YZ-3 x 4+1 x 1.5m 2 between the power supply supply terminals from the distribution box to the cabinet, and the use of sheathed wires is not allowed.

The main board of the networked computer uses DC power supply, 5V, 12V, 24V, and the power is less than 60W.

The main motor power of each cabinet is 1. 1 kW, voltage 380V and 220V.

Use "Chang Cheng" to double the efficiency! With "Chang Cheng" everything is fine!

The RFID version of the automatic layer selection filing cabinet adds RFID radio frequency identification technology, based on the original ordinary automatic layer selection filing cabinet, which has been upgraded from the original barcode management to RFID radio frequency management. After entering the magnetic field, the tag receives the radio frequency signal sent by the reader and transmits the archival information stored in the chip with the energy obtained by the lnduced the arthivarimernatou the thp withe eiergy the induced current. After the reader reads the information and decodes it, it is sent to the central information system for

relevant data processing.

The RFID management system is comprised of three parts: a reader (foreground, backstage, and host computer), an electronic tag. and an application software system. The working principle is that the reader emits radio wave energy of a specific frequency to the electronic tag, which is used to drive the electronic tag circuit to send the internal data. At this point, the reader receives the interpretation data in sequence and sends it to the application for processing. Only when there is a reading and writing device can RFID play its role. The identification system connected to the card reader has a key and a chip, which provides good encryption. The front and back readers have reading functions, and the upper computer readers have both reading and writing functions. The backstage RFID scanner group is organized by a collection of multiple scanning chips, which is different from the traditional method of scanning the inventory one by one by the scanner driven by the warehouse motor. The inventory scan speed will be much faster than that of a single scanner motor.

How it works "Power and safety protection"

- Sian sticker area:

RFID has asmaller and more convenient area. - Scan code reading speed:

The RFID scan code reading speed is several times faster than the original barcode reading speed; typically, each layer of scan code only takes about 10 seconds. - Scan the code to check its accuracy:

The reading accuracy of RFID scan codes is higher than that of barcodes and there are no issues such as blurry printing or difficulty in identifying. - Scan the code to read the penetration:

RFID scanning can penetrate all non-metallic compartments, but barcodes cannot. - Code reader convenience:

The RFID code reader is directly installed in the working panel and does not take up any space on the desktop.

- Recyclability

The chip in the RFID identification sticker can be written and read out, and recycled. - Continuous stability:

RFID code reader through the file cabinet internal electrical Label box power access is more stable. - Safety and reliability:

RFID identification stickers are attached to the files, effectively avoiding the issue of empty boxes without file storage cabinets, and ensuring more reliably.

Real World Examples

from

from