Vertical Storage Lift

Vertical Storage Lift - Vertical Lifting Module & Closed Storage

Key Features & Benefits

- Smart Storage Management – Automatically detects item height and assigns optimal storage space.

- High-Precision Lifting – Uses absolute value address recognition for accurate pallet positioning.

- Automated Operation – Supports jog, stand-alone automatic, and online automatic modes.

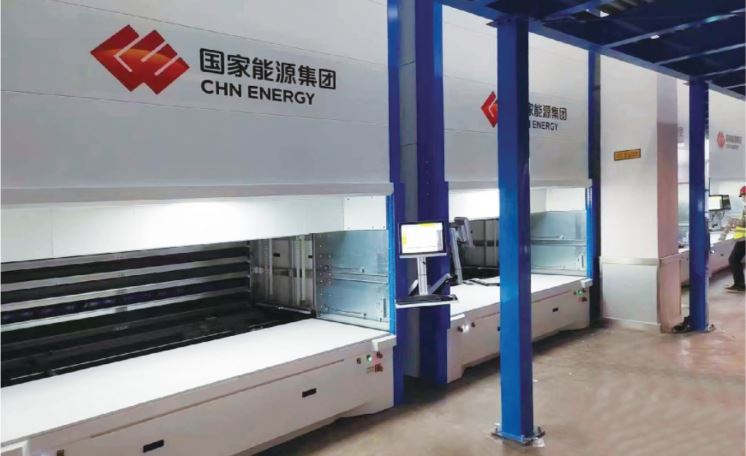

- Seamless Integration – Connects with ERP, MES, and other management systems for streamlined operations.

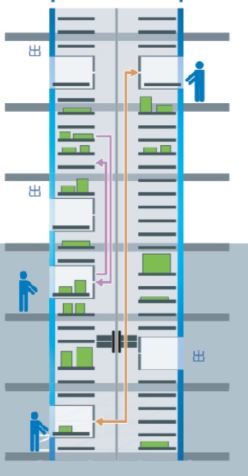

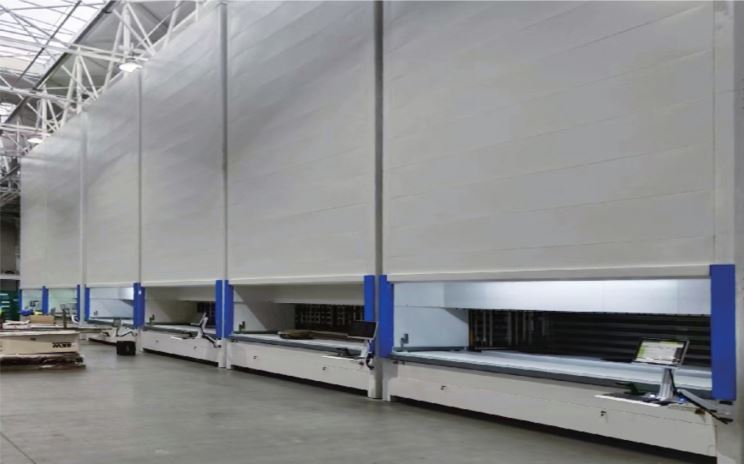

The pallet is used as the storage unit, and the pallet for storing goods is taken out or sent to the appropriate storage space in the cabinet through the lifting and horizontal movement of the pallet truck. In the lifting movement, the absolute value address recognition method is adopted, with high precision and accurate address recognition. Horizontal movement is controlled by induction. When storing, an automatic height measuring device is installed at the entrance to detect the stored items and height. The storage space in the cabinet is automatically and reasonably arranged to achieve intelligent management. With jog, stand-alone automatic, onlineine automatic a operation mode. The management monitoring system can be connected to ERP, MES, etc.

The pallet is used as the storage unit, and the pallet for storing goods is taken out or sent to the appropriate storage space in the cabinet through the lifting and horizontal movement of the pallet truck. In the lifting movement, the absolute value address recognition method is adopted, with high precision and accurate address recognition. Horizontal movement is controlled by induction. When storing, an automatic height measuring device is installed at the entrance to detect the stored items and height. The storage space in the cabinet is automatically and reasonably arranged to achieve intelligent management. With jog, stand-alone automatic, onlineine automatic a operation mode. The management monitoring system can be connected to ERP, MES, etc.

Why Choose a Vertical Storage Lift?

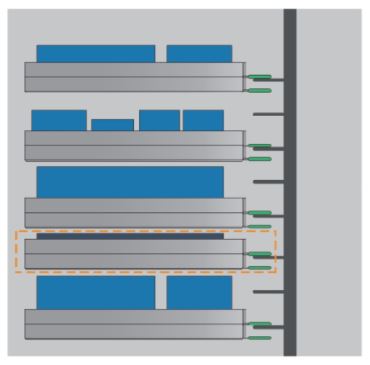

For storing items with large differences in size and irregular shapes, it offers almost perfect spatial flexibility and maximum use height up to the top of the house. Each fixed unit is 100mm high and the equipment can be adjusted to fit various plant and warehouse heights to meet requirements. If you need to relocate the warehouse or plant, the equipment can be relocated to a new location with other equipment,and thee heightht can be adjusted by adding oror subtracting subtracting module units, which is very convenient. The basic module consists of trays stored parallel to both sides of the module and an access device located in the center of the module. In each task, the vertical lift pallet can be manually set or barcode scanned to automatically place the pallet storing the goods to the desired window or corresponding number of layers. Compared to vertical rotary cabinets, lift cabinets are more suitable for items with large size differences and irregular shapes.

For storing items with large differences in size and irregular shapes, it offers almost perfect spatial flexibility and maximum use height up to the top of the house. Each fixed unit is 100mm high and the equipment can be adjusted to fit various plant and warehouse heights to meet requirements. If you need to relocate the warehouse or plant, the equipment can be relocated to a new location with other equipment,and thee heightht can be adjusted by adding oror subtracting subtracting module units, which is very convenient. The basic module consists of trays stored parallel to both sides of the module and an access device located in the center of the module. In each task, the vertical lift pallet can be manually set or barcode scanned to automatically place the pallet storing the goods to the desired window or corresponding number of layers. Compared to vertical rotary cabinets, lift cabinets are more suitable for items with large size differences and irregular shapes.

Boost the Economy

- Storage capacity can be gradually adjusted.

- It can be added, expanded, or used separately at any time in the future.

- Lower error rate, traceability reduces loss rate.

High Utilization Rate

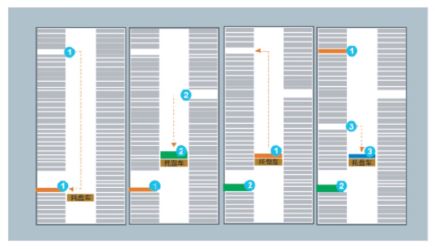

- Multiple individuals can operate container lifting and handling operations simultaneously.

- High utilization rate.

- Optimize high storage and make better use of storage capacity.

Optimization Work

- Flexible storage location selection, short inbound and outbound storage times.

- Optimization work.

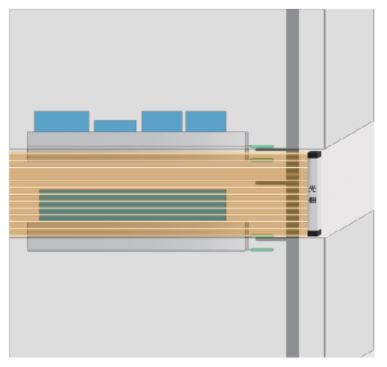

Safetygrating ensures maximum operator safety.

Flexible storage optimizes space utilization.

LDS250

Technical parameters

External dimensions (mm)

| Width | 1406~4454 |

| Depth | 2338~4338 |

| Height | 2550~12000 |

| Minimum depth increment (mm) | 95.25 |

| Minimum Height Increase (mm) | 100 |

Tray size (mm)

| Width | 1250~4000 |

| Depth | 600~1265 |

| Height | 50~120 |

| Minimum depth increment (mm) | 31.75 |

| Minimum tray spacing (mm) | 75 |

| Shelf spacing (mm) | 50 |

| Maximum load-bearing capacity of pallet (kg) | 250 |

Running speed (m/s)

| Boost speed | Full load: 0.8 No load: 1 |

| Extraction speed | Full load: 0.3 No load: 0.4 |

LDS500

Technical parameters

External dimensions (mm)

| Width | 1406~4454 |

| Depth | 2338~4338 |

| Height | 2550~12000 |

| Minimum depth increment (mm) | 95.25 |

| Minimum Height Increase (mm) | 100 |

Tray size (mm)

| Width | 1250~4000 |

| Depth | 600~1265 |

| Height | 70~120 |

| Minimum depth increment (mm) | 31.75 |

| Minimum tray spacing (mm) | 100 |

| Shelf spacing (mm) | 50 |

| Maximum load-bearing capacity of pallet (kg) | 500 |

Running speed (m/s)

| Boost speed | Full load: 0.8 No load: 1 |

| Extraction speed | Full load: 0.3 No load: 0.4 |

LDS750

Technical parameters

External dimensions (mm)

| Width | 1406~4454 |

| Depth | 2338~4338 |

| Height | 2550~12000 |

| Minimum depth increment (mm) | 95.25 |

| Minimum Height Increase (mm) | 100 |

Tray size (mm)

| Width | 1250~3050 |

| Depth | 600~1265 |

| Height | 120~160 |

| Minimum depth increment (mm) | 31.75 |

| Minimum tray spacing (mm) | 150 |

| Shelf spacing (mm) | 50 |

| Maximum load-bearing capacity of pallet (kg) | 750 |

Running speed (m/s)

| Boost speed | Full load: 0.8 No load: 1 |

| Extraction speed | Full load: 0.3 No load: 0.4 |

Equipment working conditions

| Power supply | Three-phase AC 380V ± 5% 50Hz |

| Compressed air | No |

| Work system | 7 x 24 hours per week |

| Equipment noise | Overall noise <70dB |

| Working environment temperature | 5°C-40°C |

| Ambient relative temperature | <80% |

Real World Examples

from

from